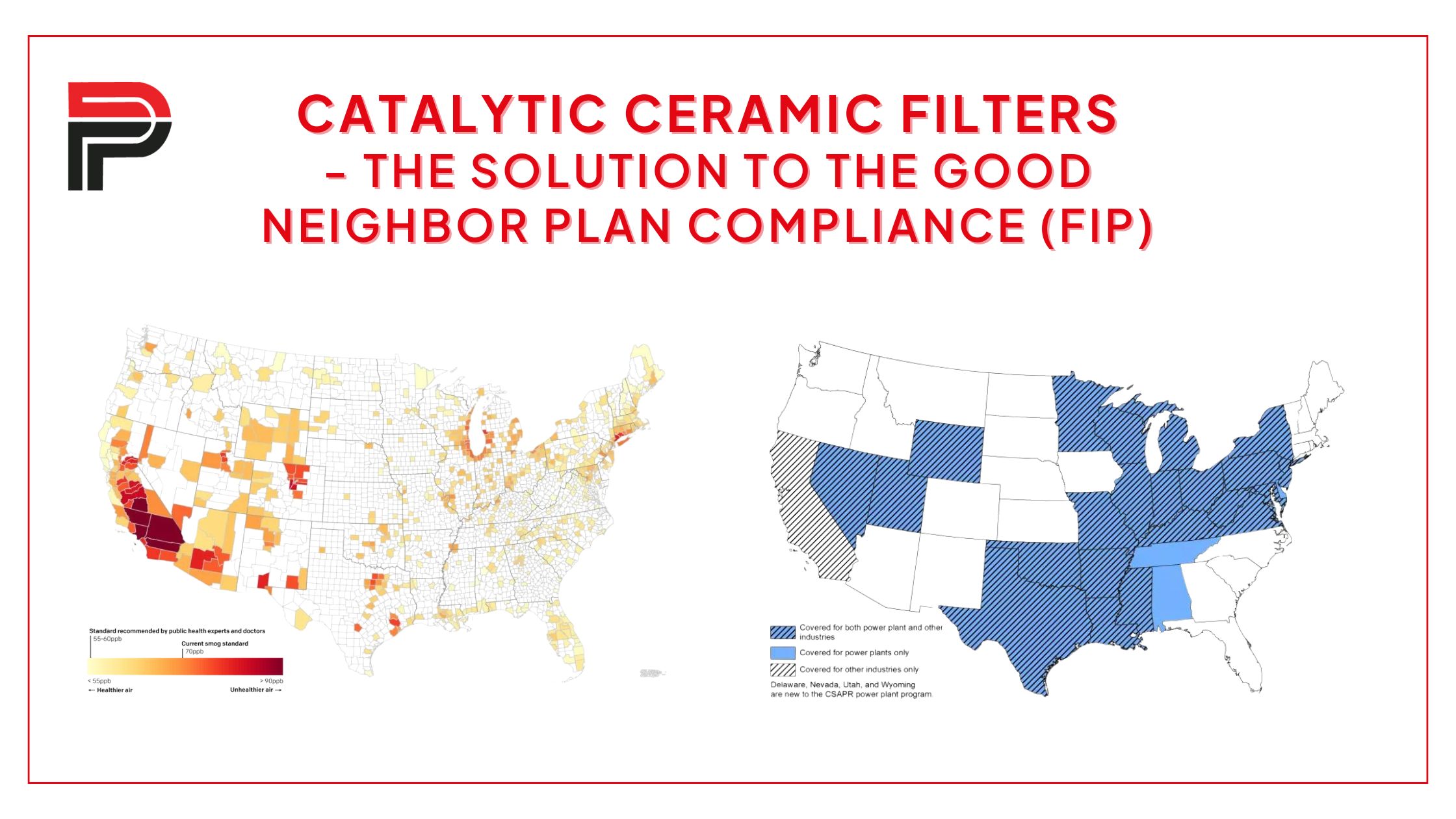

In recent years, the Environmental Protection Agency (EPA) has implemented stringent regulations aimed at curbing air pollution and improving air quality across the United States. One of the key initiatives under this effort is the EPA’s Good Neighbor Plan, which focuses on reducing cross-state air pollution, particularly pollutants like nitrogen oxides (NOx) emitted from a variety of industrial sources including chemical manufacturing, petroleum refining, metal smelting, and cement production. For many clients, innovative solutions such as catalytic ceramic filters have emerged as one of the most promising technologies for reducing NOx emissions effectively.

The Need for NOx Reduction:

Nitrogen oxides (NOx) are a group of harmful pollutants emitted during combustion, gasification, or pyrolysis processes. These pollutants contribute to the formation of ground-level ozone and fine particulate matter, which have adverse effects on human health and the environment. Additionally, NOx emissions can travel long distances, leading to interstate air pollution and violating EPA regulations, hence the need for effective NOx reduction strategies.

Catalytic Ceramic Filters:

Catalytic ceramic filters are advanced emission control devices designed to capture and convert NOx molecules into harmless nitrogen and water vapor using a deNOx catalyst embedded within the walls of the ceramic filters. We exclusively utilize Cerafil® Ceramic Filters offered by Ceramic Filter Alliance (CFA), as they are proven to provide the highest performance of any ceramic filter on the market. CFA ceramic filters are manufactured using a well-proven proprietary process, delivering over 90% NOx reduction with no performance degradation throughout the life of the filter (over 10 years), at temperatures ranging from 350F to 850F.

Benefits of Catalytic Ceramic Filters:

▪ Effective NOx Reduction: Catalytic ceramic filters have demonstrated high efficiency in reducing NOx emissions, often achieving removal rates exceeding regulatory requirements set by the EPA’s Good Neighbor Plan.

▪ Multi-Pollutant Control: In addition to high NOx performance, Catalytic Ceramic Filters are

proven to simultaneously reduce submicron particulate matter (PM), sulfur oxides (SOx), long-

chain volatile organic compounds (VOC), hazardous air pollutants (HAPs), dioxins & furans, and

many more pollutants within a single-pass-through technology.

▪ Versatility: These filters can be seamlessly integrated into existing flue gas treatment systems

▪ Longevity and Durability: Catalytic ceramic filters are engineered for durability and resistance to thermal shock and high temperatures, making them suitable for the rigorous conditions present in industrial settings. Their robust construction ensures prolonged operation and minimal maintenance requirements, contributing to cost-effectiveness and operational efficiency.

▪ Minimal Footprint: Catalytic ceramic filters offer a compact and space-efficient solution for NOx

reduction compared to other emission control technologies. Their small footprint makes them

ideal for retrofitting into existing infrastructure without significant modifications or space

Constraints.

▪ Compliance with Regulatory Standards: By effectively reducing NOx emissions, catalytic ceramic filters help industrial facilities meet stringent regulatory requirements, including those outlined in the EPA’s Good Neighbor Plan.

Catalytic ceramic filters offer a proven and reliable solution for industrial facilities seeking to reduce NOx emissions and meet regulatory requirements outlined in the EPA’s Good Neighbor Plan. With their high efficiency, versatility, and compliance benefits, these advanced filters represent a cornerstone in the quest for cleaner air and sustainable industrial practices. As industries are continuing to embrace catalytic ceramic filters, the initial investment ensures our clients are utilizing the best available control technology.